May 2011

Who among us didn't see this one coming: Offset has been dethroned by digital and will henceforth play a supporting role in small to medium sized print shops. So says a recent study by the NAPL. "No turnaround in the economy - no matter how robust - is going to change that."

Could somebody fill me in? When exactly did digital become the 800-pound gorilla in the room? Just a couple of decades ago, this upstart technology was no more than a quick and dirty solution for short runs. Offset was king and accounted for 38% of all sales for franchise printers. Today, it's less than 23%. More noteworthy still, the NAPL study also found that in shops with sales of under $1 million, only 8.1% of the respondents are planning to buy a one-color or two-color offset press in the coming years. Nearly 26%, one out of four, intend to buy a variable data digital machine instead.

While lithography still generates $40-$50 billion in sales, much of that is produced by mega shops on monster presses. In the typical Morning Flight shop, the pendulum has now clearly swung towards digital. If you haven't done so already, it's time to cozy up to the new technology. The market has a name for printers caught with old iron in the pressroom: Roadkill!

Hal Heindel

Unitac International Inc.

Getting the Quantity right

Back in the days when monitors were monochrome and users were asked to "press any key to continue", the most frequent question landing on support desks was (I'm not making this up) - "where do I find the Any Key?"

Morning Flight is known for its ease of use. We don't get many support calls. But one question that comes up regularly - more than it should - is "what do you enter as the job quantity?" I say more than it should because when you get the quantity wrong, nothing after that matters.

I may have discovered what's happening here. Some new users, often with years of estimating experience but new to pricing on a computer, tend to pre-process the quote before entering the information into the program. They calculate the number of press sheets and enter that as the job quantity, the way they used to do it with pencil and paper. Sorry to interrupt: That's not how it's done in Morning Flight.

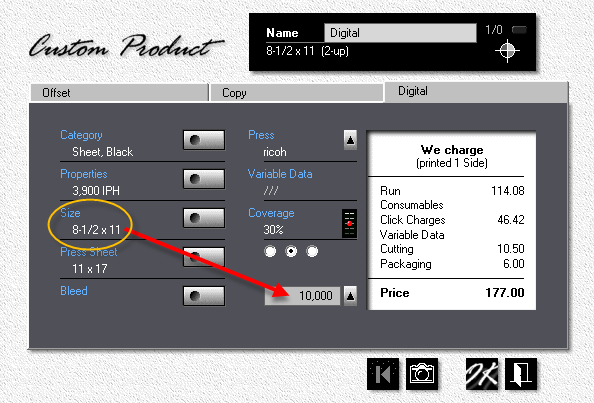

Say you're asked to price 10,000 newsletters, size 8.5x11. You decide to run the job 1-up, so you enter 8.5x11 as the size of both the product sheet and the press sheet. But maybe it would be better to run the newsletters 2-up? Easy enough to find out. Simply double the press sheet size to 11x17. The program will maintain the product quantity at 10,000 but will cut the press run in half. 4-up? Increase the press sheet size to 17x22, and Morning Flight will lower the run to 2,500. Automatically - without anyone having to push any buttons.

Here's the Aha moment. Knowing that the program will internally cut the press sheet quantity in half on a 2-up run, what do you suppose will happen when you enter the press sheet quantity instead of the product quantity into the quantity box? Right, the press sheet quantity gets cut in half twice, first by you, then by the program, and the job goes out the door for a song and your shirt. With the sole exception of pads (where you enter the total number of sheets, not the number of pads) the value you enter into the quantity box is always the number of finished pieces. Always. It's the same quantity the customer sees on your invoice.

Even with pads, it's never the number of press sheets. If a customer orders 500 memo sheets, whether you ship them loose or convert them to pads in postpress, the quantity stays at 500 regardless of how many up and on what size press sheet those memo sheets are run.

Preserving Data from a Demo

The settings you make in a Morning Flight demo are easily transferred to a paid version. All Morning Flight programs use a common set of data files, so upgrading will be seamless. Still, we're dealing with computers so it's always good policy to back up your data files (all files with the extension .TPS) before you upgrade.

To find out where those files are located, see Backing up your Data. Once your data is safe, install the paid version into your active Morning Flight demo folder, over the existing .TPS files. If any file needs updating, Morning Flight will automatically convert and transfer your data.

|

Tip of the Month

How to add Spot Colors to 4C Process While Morning Flight lets you quote offset in up to six colors, we readily concede that the program is in over its head when asked to price jobs coming off six-color presses the length of a football field. In aviation lingo, you're piloting a Boeing 737, not a C-5 Galaxy. Quoting spot colors in addition to 4C Process falls somewhere in the middle. |

When you enter ink runs for offset in Morning Flight, your predefined menu options are

Black Ink only - Black plus Color - Color Ink only - 4C Process

Note that 4C Process plus Color isn't one of your choices. Here is a workaround:

1. Select 4C Process and click Ok to close the window.

2. Reopen the same window and change the configuration to Black plus Color, then click the up arrow to show 4 ink colors. Click Ok.

3. In the window that now opens, add the spot color to the three process colors already showing.

4. Manually add color separations as custom prepress.